Port-based approach of complex distributed-parameter system models for analysis and simulation (PACDAS, STW-TWI.6012)

|

Port-based approach of complex distributed-parameter system models for analysis and simulation (PACDAS, STW-TWI.6012) |

|

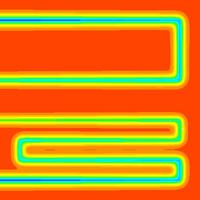

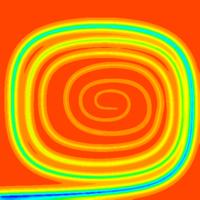

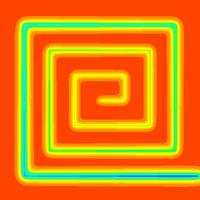

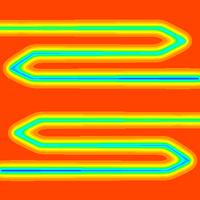

A hot press, pressing plastic forms at high temperature is cooled before releasing the form. The cooling is done by a water pipe integrated in the mould. Cold water flows through the pipe, cooling the mould, while heating the water. Near the water inlet the cooling is effective, while further along the water pipe, once the water is heated, the cooling is less effective.

For a constant flow, different geometries of the water pipe are simulated. In the case of a constant water pressure, it should be noted that, the flow will decrease with the length of the pipe.

The temperature diffuses through the mould. The water flows with a constant velocity through the pipe, displacing the water. The gird consists of 500x500 = 250 000 elements, the simulation of 30 frames, while in between each frame 300 local updates were performed. (Heat exchange between neighbours.) The flow rate is set relative to the diffusion, approximately 10 times as fast as the diffusion velocity. In the simulations with two pipes each pipe has the same flow rate.

To see the simulations running together , simulations 1 and 2 running together, simulations 4 and 8 , and 6 and 7